Milk Silo

MOQ : 10 Units

Milk Silo Specification

- Product Type

- Milk Silo

- General Use

- Industrial

- Material

- Stainless Steel

- Type

- Vertical Storage Tank

- Capacity

- 10000 - 30000 Liters (customizable)

- Weight (kg)

- Approx. 2500 kg

- Computerized

- No

- Automatic

- No

- Control System

- Level Gauge with Manual/Optional Digital Control

- Processing Pressure

- Atmospheric/Low Pressure

- Cleaning System

- CIP (Clean-In-Place) Spray Balls

- Cooling Mode

- Glycol Jacket or Direct Expansion

- Sterilization Method

- Hot Water or Steam

- Motor Power

- 3 HP (for agitator, if included)

- Voltage

- 380-415 V, 3 Phase, 50 Hz

- Dimension (L*W*H)

- Diameter 2.5-3.2 m x Height 6-9 m (customizable)

- Feature

- Insulated, Hygienic Design, Robust Structure

- Color

- Silver

- Application

- Bulk Milk Storage, Chilling & Buffering at Dairy Plants

- Outlet Valve

- Stainless Steel Butterfly/Dairy Valve

- Service Life

- > 15 years

- Design Standard

- IS, DIN or Customized

- Surface Finish

- Mirror/Matte Finish Inside, Polished Outside

- Ladder & Platform

- Provided for Operation and Maintenance

- Access Hatch

- Top Manhole with Safety Railings

- Agitator

- Optional Slow-Speed Agitator

- Insulation Material

- Polyurethane Foam or Mineral Wool

Milk Silo Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- Days

- Main Domestic Market

- All India

About Milk Silo

Our company is known as one of the leading manufacturers and suppliers of Milk Silos that can be used in dairy plants to build reliable storage facilities to store milk and other dairy products. It is fabricated by using premium-quality food-grade stainless steel that gives excellent safety to the stored products. This tank allows you to maintain the freshness of milk for a longer period by preventing bacterial growth. It is also fixed with an inlet and outlet tank to efficiently fill or discharge milk. Customers can get robust and leakproof Milk Silos with minimum order of 10 units at reasonable price.

Superior Hygiene and Insulation

Our milk silo boasts a mirror or matte internal finish and a polished outer surface, promoting cleanability and aesthetic appeal. Insulation with polyurethane foam or mineral wool ensures minimal temperature loss during milk storage and processing. The hygienic design, combined with CIP spray balls, facilitates rigorous cleaning without dismantling, safeguarding milk quality.

Customizable and Robust Construction

Designed to IS, DIN, or customer-specific standards, the silos structure accommodates a range of capacities, from 10,000 up to 30,000 liters. The sturdy stainless steel build and provided ladder-platform system enable seamless operation and maintenance. Safety railings and a top manhole protect operators during access, while a service life over 15 years assures enduring reliability.

Efficient Cooling and Mixing Options

Achieve ideal chilling and buffering of bulk milk using glycol jacket or direct expansion cooling modes. For enhanced product uniformity, an optional slow-speed agitator (3 HP motor) can be integrated. The tanks butterfly or dairy valve ensures controlled discharge, and manual or digital level gauges allow precise inventory management according to plant needs.

FAQs of Milk Silo:

Q: How is milk kept at optimal temperature in the silo during storage and processing?

A: The milk silo features double-wall insulation using either polyurethane foam or mineral wool. This efficient insulation, combined with cooling options like glycol jackets or direct expansion systems, maintains the milk at required temperatures for safe storage and chilling.Q: What is the process for cleaning the milk silo to ensure hygiene?

A: Cleaning is achieved through an integrated CIP (Clean-In-Place) system using spray balls. This automated process circulates cleaning solutions throughout the silos interior, reaching all surfaces due to the mirror/matte finish, ensuring thorough sanitation without manual entry or tank disassembly.Q: When should the optional slow-speed agitator be used with the milk silo?

A: The agitator is recommended when uniform mixing or gentle agitation is required, such as during buffering or chilling processes. It prevents milk separation and maintains homogeneity, especially in larger capacity tanks or extended storage durations.Q: Where is the silo typically installed, and what site considerations should be made?

A: Milk silos are usually installed at dairy plants storage, chilling, or buffer zones. Installation should consider adequate spacing for ladder and platform access, proper foundation for supporting approximately 2500 kg plus full product load, and ease of integration with plant processing and cleaning systems.Q: What are the benefits of the robust stainless steel construction and finishes?

A: The smooth, polished exterior facilitates cleaning and minimizes contamination risk, while the mirror or matte inside surface prevents milk residue. Stainless steel is corrosion-resistant and suitable for food-grade applications, offering durability and a service life exceeding 15 years.Q: How is the volume of stored milk monitored and controlled within the silo?

A: The silo comes equipped with a manual level gauge for volume monitoring, with an option for upgrading to a digital control system for more precise measurements. This allows operators to easily track inventory and manage milk flow during daily operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Milk Processing Equipment Category

Milk Inline Strainers

Minimum Order Quantity : 10 Units

General Use : Industrial

Material : Stainless Steel

Automatic : No

Color : Silver

Feature : Good Quality

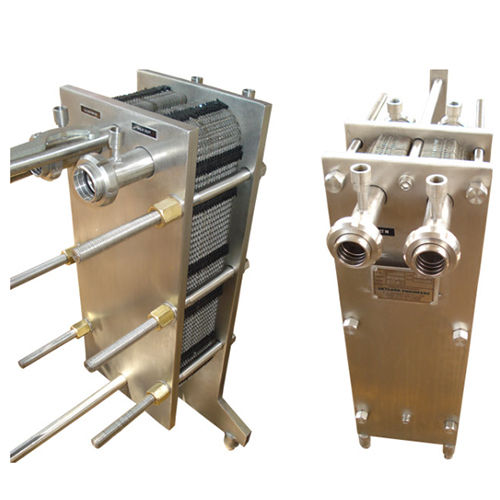

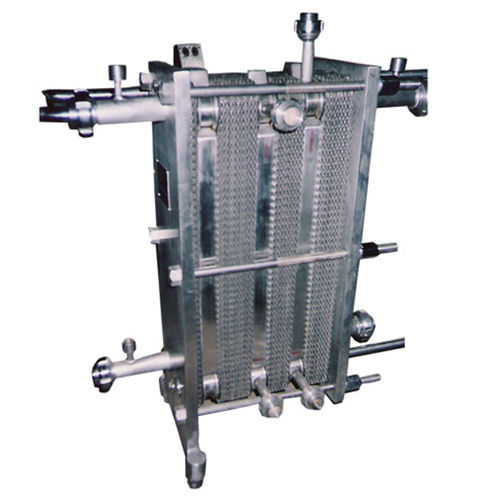

Milk Chillers

Minimum Order Quantity : 10 Units

General Use : Industrial

Material : Stainless Steel

Automatic : No

Color : Silver

Feature : Good Quality

Milk Pasteurisers

Minimum Order Quantity : 10 Units

General Use : Industrial

Material : Stainless Steel

Automatic : No

Color : Silver

|

GAUDA ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry